Why Floor and Screed Levels are Important

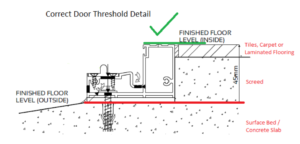

In this discussion, our primary concern is ensuring accurate door dimensions for the tailor-made production of an aluminum door that incorporates a threshold.

Upon arrival at the site for the purpose of assessing the apertures, the Aluminum Specialist immediately notices that there has been no preliminary screening and that the floor levels haven’t been fully established. Despite these initial oversights and the incomplete state of the site, the Aluminum Specialist proceeds with the measurements, driven by the client’s urgent demand for the immediate delivery of the aluminum doors.

Recommendation: It is advisable to finalize your screed levels prior to engaging with the Aluminum Manufacturer for measurements. This preparatory step ensures accuracy in dimensions, facilitating a more efficient manufacturing process.

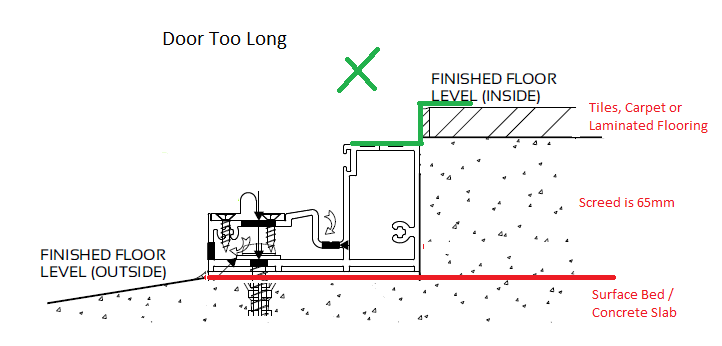

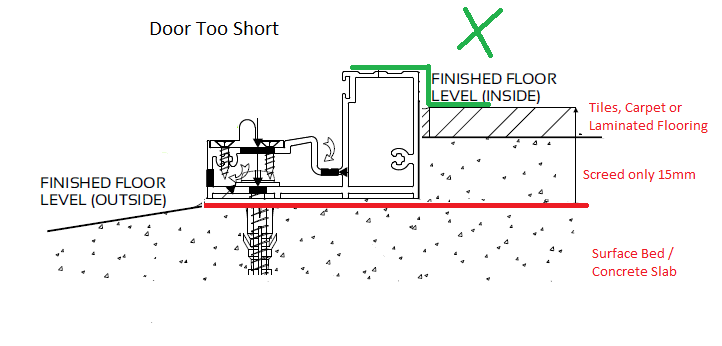

The Client will face two problematic results on site,

- Initially, the issue at hand is the excessive length of the door. This discrepancy arose because the Aluminum Contractor conducted measurements before screeding was completed. During the assessment, the contractor measured from the surface bed to the lintel, accounting for an anticipated 35mm of screed and an additional 10-15mm for tiles. Regrettably, the actual screed thickness amounted to 65mm, resulting in a door that is now disproportionate to the structure, akin to the example depicted in the following image:

- The subsequent issue is that the door is undersized. This situation stems from the Aluminum Contractor taking measurements before the screeding process was finalized. The contractor’s measurements extended from the surface bed to the lintel, incorporating a provisional allowance of approximately 35mm for screed and an extra 10-15mm to accommodate tiles. Contrary to these estimates, the actual screed thickness materialized at a mere 15mm. This miscalculation has resulted in a door that is not in alignment with the intended specifications, as illustrated in the accompanying image.

It is imperative that the Aluminum Contractor refrains from initiating measurements until the screeding process is thoroughly completed. The primary reason is the necessity to account for potential irregularities in the surface bed, which must be rectified with the appropriate screed thickness to achieve a precise floor level. Ideally, screed thickness should range from 30-45mm. However, based on experience from various construction sites, it is notable that screed thickness can vary significantly, with observed ranges from 15-95mm. This variability underscores the importance of complete screeding prior to any measurement activity to ensure accuracy in the fabrication of aluminum components.

Please Note: The Aluminium Contractor will not be responsible for reducing or increasing the door sizes. The additional cost will be for the Clients’ account. See Our Terms & Conditions.

The formula for measuring doors are as follows:

Example:

Measure Top of Screed level to the underside of Lintel: = 2135 (H) (tight measurement)

2135 – 10mm (Play)

2125 + 45 (Door Threshold) Different door systems have different threshold heights!

2170 – 15 (Allowance for Tiles, Laminated Floors or Carpet) to be confirmed with the contractors or owner

Final Manufacturing size for your door 2155 (H)

The Perfect Door Measurement!